The Rapid Fill® automated void fill packaging system from Sealed Air has revolutionized void fill by automatically inflating the bag inside the carton. The system can fill and seal up to 10 cartons per minute, doubling or tripling the speed of most traditional methods.

How It Works

A simple three step process creates ideal protection, every time.

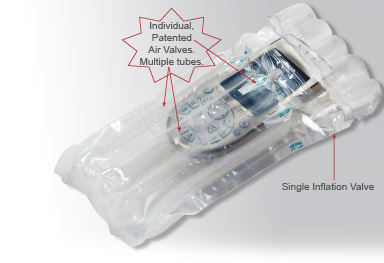

- A packer clips an uninflated Rapid Fill® bag to a corner of the carton to be filled.

- The flaps of the carton are closed, and the carton is then advanced into the Rapid Fill® system, whereit is taped closed.

- The Rapid Fill® bag is automatically inflated through the container wall. The carton is monitored for swell, indicating the correct amount of air.

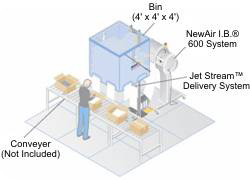

Support Multiple Work Stations

One Rapid Fill® system can support multiple pick-and-pack workstations, and the speed can reduce the number of overall packagers needed at the line. Operator interaction is minimal – insert bag, fold the flaps, and the Rapid Fill® system does the rest!

Superior Material is Lightweight and Efficient

Rapid Fill® inflatable bags use less material than traditional systems because there is no waste. The material is lightweight, on average 15% lighter than other materials, saving on transportation and shipping costs. Bags are inflated on-site, and can be deflated to less than 99% of their inflated volume, making Rapid Fill® bags more space-efficient than bulkier materials. The deflated cells can be sent to any of a number of Sealed Air locations where they will be recycled back into LDPE.

The pulse of the packaging community