The manufacturer was wrapping the rolls in a cocoon pattern using 135 gauge film at 150% prestretch with high film force. When the load was picked up by the clamp truck the unsupported bottom rolls sagged 3 inches, which was unacceptable.

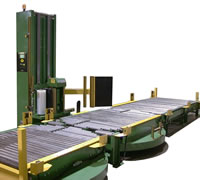

Highlight Stretch Wrapper Solution:

Highlight developed a strategic solution aligned with the client’s needs for a strong and durable package solution. Highlight used its decades of experience and exclusive programmable two stage pre-stretch technology to meet the demand. Utilizing Highlight’s Infinity Stretch (electronic variable pre-stretch) System, two prestretch settings were used during the wrap cycle to optimize stretch film performance. The first cycle used a high prestretch above 300% to give the film strength. The second cycle used a lower prestretch setting below 200% to maximize abrasion resistance to protect the highly stretched internal layer from wearing against the ground. This combination provided a strong and durable stretch wrap solution that only Highlight could deliver.

Solution Results:

- Eliminates the need for pallets

- Optimization of stretch film prevented re-stretch from unsupported rolls

- Reduced film consumption by 20%

- Package holds up to extreme abuse exceeding the customers’ expectations

The pulse of the packaging community