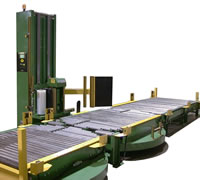

Highlight Synergy™ 5 Conveyor Fully Automatic Stretch Film Wrapper

Last updated on

Highlight Industry’s Synergy™ 5 Conveyor Automatic is the industry standard for conveyorized turntable stretch wrap systems! Infinitely adjustable Dual Power Hydro-Stretch® allows ultimate stretch film control with maximum load security.

State-of-the-art touch screen controls provide reliable operation, as well as diagnostic indicators for troubleshooting.

Highlight-built conveyors ensure heavy duty capacity, long life, and fast, smooth conveying for high production rates.

Highlight’s Synergy™ 5 Turntable Stretch wrap system is designed for maximum productivity and minimum maintenance using Allen-Bradley PLCs and off-the-shelf components. The Synergy 5 offers complete control over every aspect of your stretch wrapping needs!

Wrapper with Film Fingers and Slitting System

- 50–60 loads per hour

- 48″ wide x 50″ long maximum

- 38″ wide x 38″ long minimum

- 20″–72″ standard wrap height

- 52″ effective width

- 60″ length

- Powered turntable transition rollers

- 3¾” roller centers

- 2½” diameter rollers

- Every roller driven

Wrapper with a slitter using black stretch film

- Dual Power Hydro-Stretch®

- Film Stretch: Infinitely adjustable from 0% to film’s maximum

- Independently adjustable film force

- Film clamps

- Film wipe down arm and Teflon® coated hot cut bar

- 20″ film capacity x 10″ diameter

- 37″ diameter ring gear table drive

- 84″ diameter turntable

- Individual top and bottom wrap counters

- Allen-Bradley PLC

- Air: 80 psi, 3 cfm

- Electrical: 240/480 volt, 3 phase, 15 amp

- “Off-the-shelf” components

Custom Synergy 5 Wrapping Solutions

This high speed coil wrapper roper is engineered wrap coils of steel and aluminum to a pallet

This custom solution was a foam and film wrapper for cabinets

This wrapper is using a net to secure boxes to the pallet

The pulse of the packaging community