FillPak Void Fill System

Last updated on

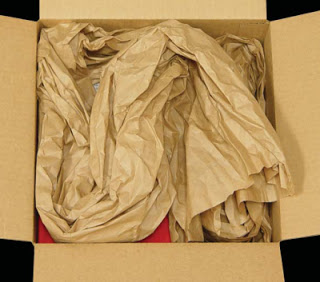

The FillPak void fill system converts kraft paper into a PaperStar output configuration and is the most efficient way to fill an empty space within a cardboard box. Everything from the shape of the PaperStar, to the height of the machine, to its speed and operation has been designed to maximize throughput and minimize cost in high speed void-fill packaging operation.

FillPaks Advantages:

Cost Effective

FillPak is the fastest, most economical void-fill system on the market for high volume high speed packaging applications. Ranpak’s geometrically shaped PaperStar configuration is the most efficient way to fill an empty space inside a box and will yield material cost savings of 20% or more.

This FillPak system has been designed to reduced down time by holding up to 700 cubic feet of packaging material – typically enough for one shift and designed to provide packaging material at up to 55 inches per second.

- 1 – Box yields 100 cubic feet of packaging material

- Fan-fold maximizes paper – minimizes air

- Fan-folding allows for very high operating speeds

- Each box of paper includes tape to connect to the next box

- Each box has handles for easy transportation and loading

- Stack up to 7 boxes on a FillPak converter, enough to generate 700 cubic feet of packaging material on-demand.

Speed – 3 Operating Speeds

- 30 inches per second

- 45 inches per second

- 55 inches per second

Operation: Footswitch

Packing Height: 0 to 66 inches

Yield per Box: 100 Cubic feet

Fan-fold FillPak Paper

Saves Storage Space: The FillPak system takes up significantly less storage space than competitive products. One box of FillPak paper provides more than five, 20 cubic foot bags of loose fill. One pallet of FillPak paper material will yield 3,000 cubic feet of packaging material. That would compare to 150, 20 cubic foot bags of loose fill material.

FillPak material is made from all-natural kraft paper. It is 100% biodegradable, recyclable and renewable. FillPak is the right choice for anything you might want to protect, including the environment. Most competitive products are petroleum-based: non-biodegradable, and non-renewable materials. In fact, most plastic packaging materials have a half-life of several hundred years.

The FillPak system converts single-ply kraft paper for top and side void fill applications. The paper is 100% recyclable, biodegradable and reusable and, on average, is made from 35% recycled material.

A Ranpak sales representative can help you determine what product best suits your needs.

Type |

Weight (lbs.) |

Lengths Available (ft.) |

Application |

| FillPak | 30 | 1,660 | Top and Side Void Fill |

| FillPak 100% Recycled | 30 | 1,660 | Top and Side Void Fill |

| FillPak TT 100% Recycled | 30 |

1,660

|

Top and Side Void Fill |

| FillPak TT | 30 | 1,660 | Top and Side Void Fill |

| FillPak TT | 45 |

1,200

|

Top and Side Void Fill |

Specialty Papers:

|

Most Popular Related Items

About VoidFillPackaging.com

Welcome to Void Fill Packaging, a site that showcases packaging systems, talks about packaging products, and what’s new in the industry. We provide a place for product research, discovery and discussion. Take a look around and be sure to stop by again to see whats new!Ranpak Paper Fact

Ranpak only works with Sustainable Forest Initiative (SFI) or Forest Stewardship Council (FSC) certified mills to ensure their material comes from a responsible source and that sustainable forestry practices are taking place.

Thanks to this sustainable forestry management, forests in the United States are growing every year. The forest products industry plants more than 1.7 million trees per day, growing more than is harvested each year. According to the Society of American Foresters, there are more trees now in the United States than there were in the 1920s.

The pulse of the packaging community