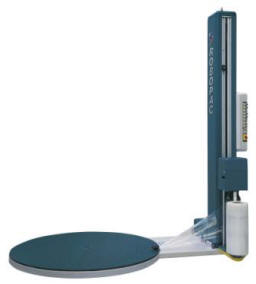

Robopac Jolly by Aetna

Last updated on

The Jolly line is designed for dynamic, rapidly growing companies that require maximum priority and flexibility stretch wrapping operations with a limited investment. Jolly machines are now available featuring different wrapping functions and film delivery system. In particular, the new Jolly PPS is equipped with a powered pre-stretch film carriage with fixed pre-stretch and adjustable force to load. Like all Robopac machines, the models of the Jolly line are built according to the highest quality and safety standards.

Attention to the production process and the use of high-performance materials place this product at the top of their category.

Update: The Robopac Ecoplat Stretch Film Wrapping Machine has replaced this model.

An entry level pallet wrapper; semi-automatic turntable stretch wrapping machine. Its technical specification, performance and price make it the ideal alternative to manual or joystick-operated wrapping machines.

The Robopac Jolly PPS is a machine which has advanced wrapping functions, a plate for use with trans-pallets and furthermore is equipped with a carriage with motorized fixed ratio pre-stretching. In particular, the machine is offered with 200% pre-stretching, but can also be ordered with 150% or 250% pre-stretching. In addition, three additional pre-stretching kits (150%, 200% and 250%) are available on the list. Another very important feature is that on the Jolly PPS it is possible to check the pull of the film which therefore becomes independent from the movement of the load to be wrapped. This control takes place using a mechanical dandy roll which can be adjusted manually. The Jolly PPS has, therefore a high level of control over the forces in play during the wrapping process with stretch film.

Distinguishing Features

TURNTABLE

Heavy duty casters with sealed bearings. A chain and sprocket system ensures consistent and reliable turntable performances during rotation.

MAST

The mast is made of cold folded steel and has a tubular inner structure in order to ensure maximum rigidity and resistance to any torsion or strain. An heavy duty drive chain moves the film carriage upward and downward for a constant and accurate control of the wrapping process. The anti-fall device in case of emergency assures the maximum safety.

HOME POSITION

The load always stops in the same position that was placed in before the wrapping. This greatly improves times and costs of the process. Plate’s smooth start and stop steps are controlled by VFD that provides consistently the same positioning of the load before and after the wrapping cycle. The gear and worm system makes it possible to keep the phase of the turntable even while positioning the load on the plate.

Technical Features

| MACHINE | Jolly Power Pre-Stretch (PPS) Manually interchangeable fixed gears powered pre-stretch |

| Plate diameter | 65″ |

| Turntable rotation speed | 4÷10 rpm |

| Fork-lifting Power Pre-Stretch | Front and Rear |

| Power supply voltage | 120 Volt 1 Ph/60HZ |

| Installed power | 1.5 HP |

| Phase stopping | STD |

| Soft start | STD |

|

Characteristics of the product to be wrapped

|

|

| Maximum dimentions (LxW) | 48″ x 48″ |

| Maximum useful height | 86″ |

| Maximum load weight (PPS) | 4400 lbs |

|

Film roll characteristics

|

|

| Maximum external diameter (D) | 12″ |

| Film roll height (h) | 20″ |

| Film thickness | 70 ÷ 140 gauge |

| Internal diameter (d) | 3″ |

| Maximum weight | 44 lbs |

The pulse of the packaging community